Recent searches

Search options

#mueslitech

#MuesliPLC (wired)

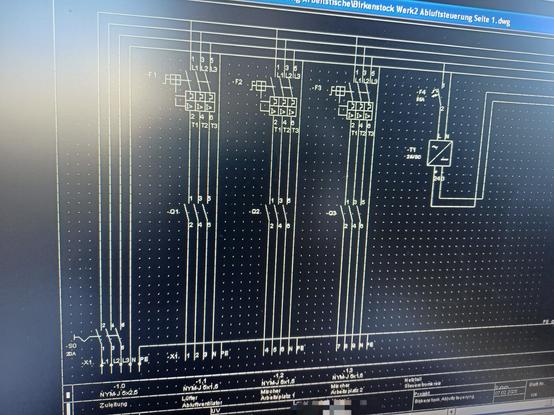

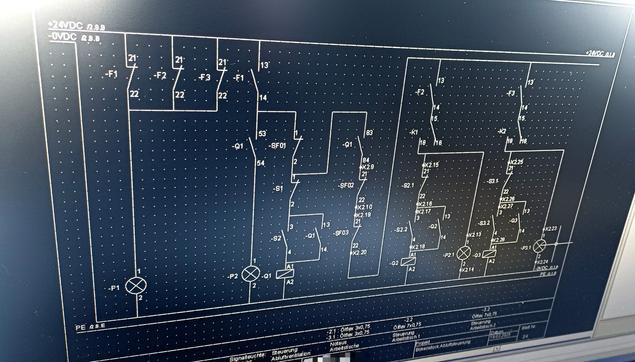

Today, I finally created the circuit diagrams. Until now, there was only my scribbling.

Let me give you some context:

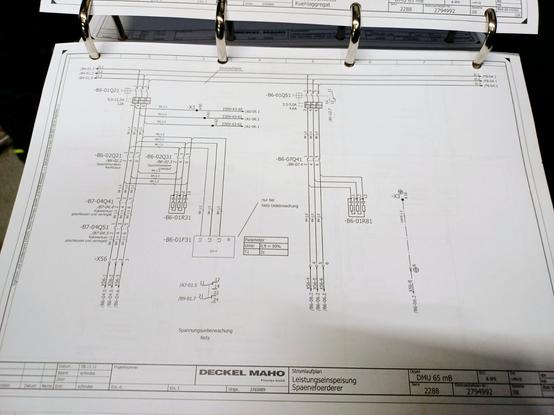

I was actually only working on the machine because a pump had stopped running. The error message was already showing on the control screen, but the CNC machine kept running. The worst that could have happened was the coolant collection tank overflowing.

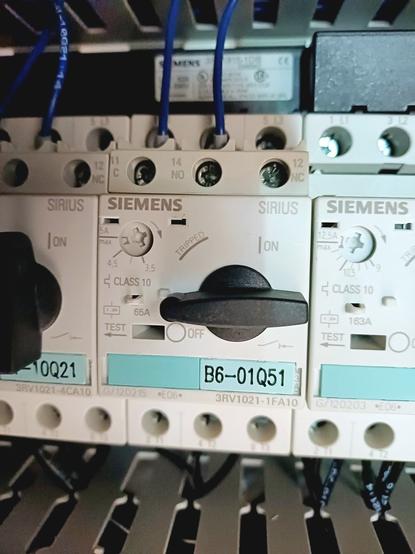

In any case, the transfer pump wasn’t running, and the motor protection switch kept tripping after a few seconds.

I measured the windings on the motor, but everything was fine. Now I’d love to know what the pump was thinking, lol.

Anyway, everything was electrically sound, and the motor protection switch did exactly what it was supposed to do to prevent damage.

After cleaning the collection tank and the pump, everything should be working again.

Fancy a bit of PLC? No?

Never mind, here we go!

#MuesliPLC #MuesliTech

#Siemens #Simatic #SINAMICS #CNC #machine #industry #PLC #ProgrammableLogicController #SPS #SpeicherProgrammierbareSteuerung

I should get in the habit of showing the completed projects...

What do your #UPS units look like?

This is what the exhaust control system looks like with the control cabinet housing and door.

The cable tray and DIN rails are riveted in place, and I've started with the wiring

From this point on, I had to plan and draw the control circuit. Of course, it will be properly done in the end. But for now, the sketch will have to do.

Basically, it's like PLC programming with ladder logic, just with real wiring.

First preparations for the announced ventilation control.

There isn’t much space on the mounting plate.

I have a new project. I would classify it under #PLC, even though it is #hardwired.

It's about an exhaust control system for two workbenches in an explosion-protected area.

Basically, it's a series of safety chains to ensure that the machines only run when the exhaust fan is operating. Both workbenches will be monitored by an airflow sensor, which must be routed through a zener barrier.

I will try to show some of this tomorrow.

As previously mentioned, the distribution system was installed today.

In the first picture, you can see how it looked before. Only a few preparations were made, such as removing the side covers and drilling holes for wall mounting.

In the second picture, the distribution cabinet has been installed next to it. I took the photo around midday, and the wiring was essentially completed. The existing wiring was replaced with new wiring leading to the #KNX cabinet.

Since most of the programming was already done, I just had to add the labels during testing.

Tomorrow, the work continues with fine-tuning. I already set the runtime for the awnings today. Tomorrow, I’ll need to reconfigure the dimmers with an adjusted dimming curve for each lamp.

Alright, time to share something new again. This time, a bistro is getting retrofitted with #KNX. Since the electrical installation is only a year old and all the wiring runs through terminal blocks to the distribution cabinet, it’s quite straightforward to implement. A slim distribution cabinet will be added, containing the actuators, binary inputs, and the visualization server.

I already programmed the system last Thursday and configured the server as much as possible. Installation and switchover will take place on Monday and Tuesday.